Making A Porous Ceramic Filter

The invention relates to a method for production of a porous ceramic body and a corresponding ceramic body which finds application in particular as filter or filter membrane in cross flow filtration.

Making a porous ceramic filter. Ceramic foam is an important part of porous ceramics and the open cell type of ceramic foam which is a new type of highly porous ceramics has a three dimensional reticulated structure with connective pores resulting in great specific surface area high fluid contact efficiency and a small loss of fluid pressure 26 27. Get it as soon as fri sep 25. Free shipping by amazon. There are several methods used to make ceramic filters.

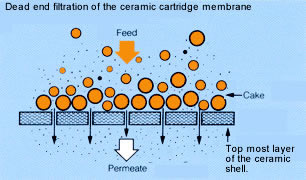

The introduction of 3d printing technology into the porous ceramic industry provides greater speed and flexibility eliminates tool constraints needs only low cost investment and enables the sustainability of the additive manufacturing process. According to the invention a bimodal ceramic powder mixture is moulded to give a moulded body then subsequently recrystallised by curing at high temperature such that the fine particles melt. The polymeric sponge method which will be described in more detail here produces open cell structures by impregnating a polymeric sponge with a ceramic slurry which is then burned out to leave a porous ceramic. Mantec filtration specialises in the manufacture of the star sep ceramic membrane which has been specifically developed for energy efficient crossflow microfiltration.

The 3d printing can be used in the making of porous ceramics in a different of applications. After drying the sponge in an oven it is biscuit fired at 350 c. New porcelain ceramic filter with dripper white b028 japan import 3 8 out of 5 stars 42. Contaminated water is poured into a top container.

It also does not filter out minerals like calcium and magnesium meaning there is no need to pair the filter with a remineralizer if you want to preserve the mineral quality of your water. A sponge is then dipped into the slurry to adsorb the slurry. In this research project the microbiological quality of the water processed by a low cost newly developed micro porous ceramic filter is evaluated. Wffo aquarium porous ceramic filter media net bag biological ball fish tank.

It passes through the filter s into the receptacle below. A process for manufacturing a porous si 3 n 4 ceramic filter wherein silicon powder the raw material methyl cellulose the binding agent and water the solvent are well mixed together to obtain a slurry. The lower receptacle usually is fitted with a tap. Mantec s range of porous ceramic filters removes solids from air gas and industrial liquid processes such as water chemical and petrochemical products.

For 2 hours and then sintered at 1200 1400 c. What ceramic filters don t remove. As 66 of the human body is made up of water. Ceramic filter systems consist of a porous ceramic filter that is attached to or sits on top of a plastic or ceramic receptacle.